The Competition for Leadership when the Market for Progressive Lenses became global

Summary:

The following article describes the era following the first appearance of progressive power lenses (PPL) which was a period of remarkable sales growth, and tells the story about competition for market share and for market leadership. This period between the end of the 1970’s until the end of the 1990’s were the years after the breakthrough invention by Bernard Maitenaz of Essilor and the launch of Varilux 2. Competition adopted the new concept and using their distribution channels accelerated the penetration of this innovative lens type. Rodenstock and Zeiss in Europe, Seiko and Hoya in Asia and AO and Sola in the USA created new design ideas which improved further the efficiency and comfort of the progressive lenses. Particularly from the middle of the 1980’s with the entrance of Sola with VIP Essilor’s dominance of the PPL market was under fire, particularly in the US.

As a response Essilor renewed the image of its flagship lens Varilux using the Multi Design concept in association with the “boucle dioptrique” development method. This design loop allowed a continuous improvement by direct involvement of the wearer in the optimization process and was a first step to the personalization of the PPL’s . The launch of the Multi Design Varilux Comfort was a turning point in this battle for market leadership.

The first patent of a progressive lens was granted to Owen Aves in 1907 (UK 15 735). In this invention the progressive power was the result of the combined effect of a progressive cylindrical front surface with horizontal axis and a conical back surface apex downwards. There were other proposals creating the progression with both surfaces, a concept which had the advantage to use surfaces of revolution easier to manufacture, but the inconvenience that at that time it was difficult to incorporate the prescription in the second surface contributing to the progression.

The history of the beginning of the progressive lenses is analyzed in detail in several publications for example by Sullivan and Fowler [1], and Maitenaz [2].

To preserve the second surface exclusively for the correction of the ametropia means to realize the power increase from far vision to near vision on only one surface. Usually the line of the surface corresponding to the path of the converging eye for central vision is called the principal meridian. According to the laws of differential geometry, it is only on the principal meridian where the progression power can be spherical (umbilical line). To both sides of this meridian there is surface astigmatism increasing to the edge of the surface (Minkwitz theorem).

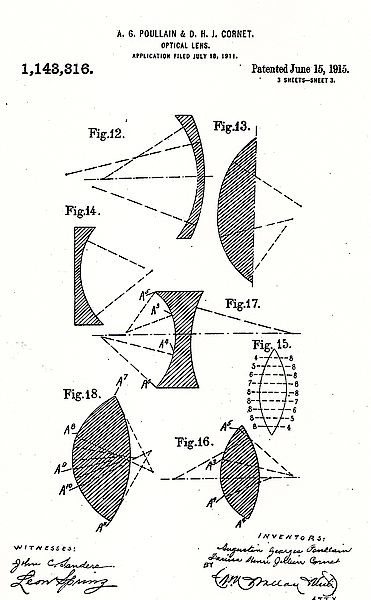

Patent G.Poullain and J. Cornet:

In a remarkable patent (US 1 143 316, application 1911) the French inventors Georges Poullain and Julien Cornet present different progressive lens concepts including a design with an umbilical main meridian, circles as orthogonal sections and stabilized far and near vision zones. In other examples a power increase at the bottom of the lens enables the wearer to see the ground at his feet and also where each of the two surfaces has a progressive main meridian. But there is no discussion of the lateral optical quality and little about the manufacturing process. The patent says about the process of manufacturing:

“In order to obtain the surfaces indicated above, the methods ordinarily employed by opticians for cutting spherical, cylindrical or toric lenses would not be suitable and that it would be necessary to have recourse to special machines”

In a first patent filed in 1932 (US 2 001 952) Henry James Birchall briefly described (not part of the claims) a manufacturing method for a progressive lens with circles as orthogonal sections. In a second patent filed in 1945 (US 2 475 275) he describes qualitatively how the curvature of the orthogonal sections has to evolve from the main meridian to the edge of the surface in order to reduce the lateral distortion. This is also the goal of Kanolt who in his patent US 2 878 721 (application 1954) gives a mathematical description of special surfaces which are calculated to respect certain thresholds of the peripheral astigmatism.

So up to the fifties certain basic elements characterizing the structure and the performance of progressives were known, but the patents describe almost exclusively the geometry of the surfaces and do not address the problem of how to realize the lens. Bernard Maitenaz supposes [2] that the optical industry was rather satisfied with the bifocal correction and the research efforts were moreover concentrated on the minimization of aberrations instead of creating new designs which inevitably have surface astigmatism in the periphery.

Bernard Maitenaz (middle), Dominique Meslin (left), 2009

When Bernard Maitenaz started his career with the Société des Lunetiers (SL) his mission was not to develop a progressive lens but to improve the manufacturing process for mineral lenses. The Essilor history and the development of Varilux and Varilux 2 are presented in [3]. In the beginning it was his personal project to develop a new lens correcting presbyopia in a more natural way than a bifocal does. But as a consequence of his education as an engineer the theoretical concept of a lens providing a continuous vision in all distances made only sense for him, when there were the technical means to produce it. This was the decisive difference between him and the scientists and inventors having previously worked on the concept of a progressive lens.

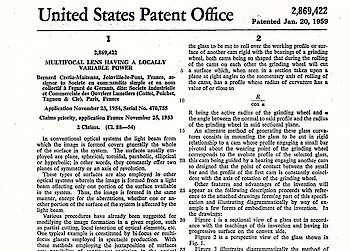

The first patent by Bernard Maitenaz, application date France, November 25, 1953 (here the US version US 2 869 422)

So already in his first patent, filed November 25, 1953 in France he defined a progressive lens together with two proposals for manufacturing methods. The progressive design was characterized by an umbilical line and a circle as the generatrix curve. The different stages of the development of the lens design and the manufacturing method are described by Bernard Maitenaz in “Four steps that led to Varilux “ [4]. In the following years between 1955 and 1959 Bernard Maitenaz filed four patents US 2 915 856, US 3 021 647, US 2 982 058, and US 3 041 789. In the first patent “Machine for Grinding an Optical Surface in a Piece of Refractive Material” the generating surfaces are more complex than the circle generatrix in the first patent, resulting in orthogonal sections as for example parabolas, ellipses or hyperbolas. The second patent protects a machine for honing, the manufacturing stage between grinding and polishing of the progressive surface. The third and fourth patents are the basis for manufacturing progressive lenses by a copy process using a point to point machined steel alloy model.

In 1959 the Société des Lunetiers successfully launched Varilux – the first commercial progressive lens

The launch of Varilux 2 in 1972 was the next fundamental step in the history of the progressive lens. The design of this lens abandoned the prevailing idea for spectacle lens construction that the visual perception is mainly dominated by foveal and static vision. So a bifocal was considered up to that time as a good correction for presbyopic people and even Varilux was still characterized by almost spherical far and near vision parts. And for the same reason the lateral aberrations of a progressive lens made it unacceptable for some experts strongly influenced by the concept of point focal lenses, notably in Germany [3].

Surprisingly if one talks with people wearing PPL’s of modern design many of them do not perceive these aberrations. Bernard Maitenaz understood that that the lens designer had to take into account the whole complexity of the visual process, that it is not only static and foveal, but also dynamic and peripheral. The result of taking into account this global character was the creation of a totally aspheric design for Varilux 2. The new surface had excellent “orthoscopic” properties, that means that in the lens periphery it preserved the direction of vertical and horizontal lines, which are so important for orientation in our daily life. Low levels of astigmatism and aberration gradients guaranteed a high quality of dynamic vision. The experts called Varilux 2 a „soft“ design with a low level of aberrations compared to the “hard spherical” surface of the first Varilux.

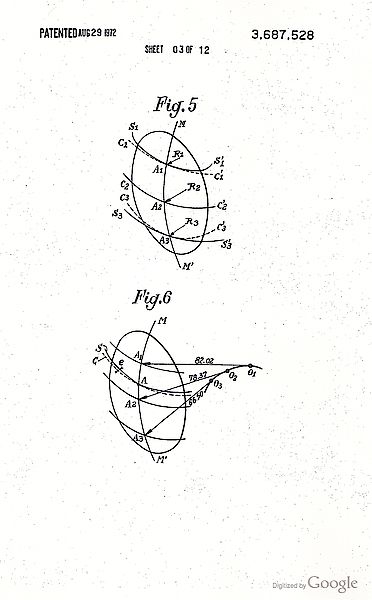

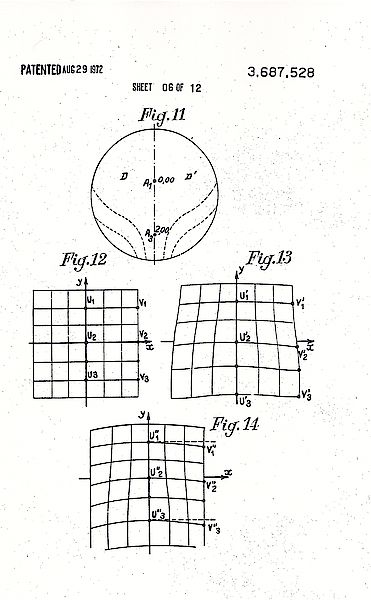

“Patent Varilux 2” (US 3 687 528): “optical modulation” and ”orthoscopy”

The new concept of Varilux 2 is laid down in a patent filed in France in September 1969 and which has the US patent number 3 687 528. In the upper part of the lens the curvature of the orthogonal sections increases in the periphery and decreases in the periphery in the lower part of the surface. In the marketing documents of the Varilux 2 launch this curvature change of the orthogonal sections is called “Optical Modulation” and in a first approximation the orthogonal sections were “evolutive conics” which means that from the top to the bottom of the lens the sections were flat ellipses, a circle, elongated ellipses, a parabola and hyperbolas.

Another patent application was filed in France in 1966 (US patent 3 785 724) which covers the progressive surface with asymmetric structure i.e. a particular surface and a separate manufacturing for the right and left lens. July 1972 is the application date in France of a further patent US 3 910 691 with extensive claims limiting the curvature difference (depending on the add power) between a point on the main meridian and the horizontally corresponding point of any section between the surface and a vertical plane parallel to the main meridian.

The overall aspheric design of Varilux 2 was an enormous progress, it was the birth of the modern progressive lens .The number of non adapts to the new soft lens was very small, primarily due the excellent peripheral and dynamic vision properties but certainly also thanks to the increased experience of the ECP’s in prescribing and centering PPL’s. So Essilor sales of progressive lenses increased strongly and reached about 3 million per year in 1975 [3], at a similar time when American Optical launched its progressive lens.

The order of magnitude of the potential market was about 100 million lenses, as a rough estimate shows. To penetrate the market with a new product is a slow process, particularly if there is only one manufacturer of the product on a market, where the distribution has very often its favorite supplier. But not only the opticians and ophthalmologists were increasingly convinced that the progressive lens was a superior solution for presbyopes, but also the other manufacturers discovered the new product as an excellent opportunity to upgrade their product portfolio.

In the first half of the 1960’s in the USA Univis launched the Omnifocal , a progressive with a front surface of revolution with substantially constant astigmatism over all the surface. This “isostigmatic” front surface was combined with a back surface of sphero-cylindrical power resulting from the superposition of the compensation cylinder and the prescription. This concept was presented by David Volk and Joseph Weinberg in 1962 [5] and the manufacturing process of aspheric surfaces of revolution was patented in US 3 239 967 (filed 1963) and the lens design in US 3 623 800 (filed 1969).

In 1975 when American Optical launched its Ultraview 25 (AO 7 in Europe) [6],it was the world leader in turnover in the Ophthalmic Optics industry. The optical design was conceived by John Talley Winthrop and protected by three patents filed in 1975 (continuation of a first application in 1973): In US 4 056 311, US 4 062 629 and US 4 055 379 he describes progressive surfaces with lateral zones in which the principal axes of astigmatism are horizontal and vertical. These portions are blended either by particular aspheric areas or by the thermal slumping process of the mould. The AO Ultraview was of the” hard design” type with spherical far and near vision zones and a short progression. It was a progressive design tailor made for the important US bifocal market.

As before in Europe the introduction of the new lens type on the US market was not easy because the ECP’s had no experience with progressive lenses. Consequently at the beginning the return rate due to centering and adaptation problems was rather high. In 1975 Essilor created MOC, the US subsidiary for the Varilux distribution. Based on the experience during the Varilux introduction in Europe the strategy of MOC was a thorough training on the specific characteristics of the new lens. This training was organized for the ECP’s and a limited number of labs, selected for the Varilux distribution.

So at the beginning in the US the challenge for Essilor was less to fight against competition but to do the pioneer work to educate and convince the market of the benefits of the progressive lens. This situation changed fundamentally in 1985, when SOLA launched its first progressive lens VIP.

Rodenstock Progressiv R: In the 1970’s Rodenstock was the leader on the German spectacle lens market, which was the principal market in Europe. In their product portfolio they had a progressive lens from BBGR with the name Zoom , which had an optical performance inferior to that of the Varilux 2 design. In Germany Varilux 2 was not only sold by the company Ehinger, the German distributor of Essilor, but also by Rodenstock’s big competitor Carl Zeiss under the brand name Gradal 2.

So Rodenstock decided to develop its own product

Rudolf Barth (left), Günther Guilino (right) (1982)

Randolf Rodenstock (left),Rudolf Barth (middle),Werner Köppen(right),(1983)

Günther Guilino, the Head of the Optical R&D department and Rudolf Barth were responsible for this project. The challenge was to catch up in a few years the advance of Varilux 2 based on a research work of nearly 20 years. Progressive R, the first progressive lens developed in Germany was launched in 1981.

The backbone of the design was an umbilic principal meridian and the horizontal sections perpendicular to the main meridian were so called surfaces with variable periodicity (patent US 4 315 673, filed 1978 in Germany). They provided a platform for a design with large stabilized viewing fields for far and near vision and a moderate level of peripheral astigmatism. The design was symmetric, so that near vision decentration was achieved by a nasal rotation of the lens.

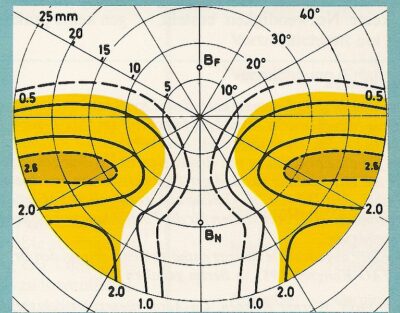

Progressiv R: surfaces of variable periodicity (left) and iso-astigmatism plot

As a new tool to assess the quality of the new design and to develop it iso-astigmatism lines and lines of constant mean power were used. Werner Köppen responsible for Physiological Optics organized the physical-physiological measurements as well as the wearer tests necessary for the optimization of the new lens. Measurement of the visual acuity of Progressiv R wearers confirmed the large viewing zones for far and near vision free of aberrations. In the wearer tests Progressiv R was compared to two competitors’ lenses by more than 100 wearers. Using the double blind methodology the results served to optimize the design and as final control before the launch. With an excellent mark of 2.1 for the global performance and comfort (marking from 1=excellent to 5=poor) Progressiv R was rated superior to the 2 reference lenses. The goal to develop a lens with comfort and adaptation at least equivalent to Varilux 2 was achieved [7],[8].

As concerns the determination of far and near vision power for the Progressiv R lens , the recommendation for the optician was to take the values measured by refraction as customary for single vision and bifocal lenses. This was the marketing argument saying that with Progressiv R the optician works as usual, whereas for Varilux 2 the suggestion common on the German market was that to obtain optimum comfort the refracted far vision power should be changed by -0.25 D and the add power increased by 0.25 D.

Karl-Heinz Pickelmann (1979)

In Germany the Rodenstock Sales department under the responsibility of Karl-Heinz Pickelmann organized a powerful market introduction with a well balanced mix of promotion and scientific presentations by the R&D people. Frank Jaursch, responsible for Export introduced the new product mainly with the help of Rodenstock distributors. The new lens was a big success on the market and for some years Progressiv R was number 2 in the global PPL market share ranking.

The fact that Rodenstock had only a small number of owned subsidiaries outside of Germany was certainly a drawback in the long run for the development of Rodenstock. But in 1980 Rodenstock’s turnover was about the same as Essilor’s.

Zeiss Gradal HS: The success of Progressiv R on the German market obliged the other big German manufacturer Carl Zeiss to follow with a new proprietary lens in order to upgrade the image of Gradal and to regain lost market share. At that time Bernd Kratzer was Head of the Carl Zeiss Ophthalmic Optics R&D and Wolfgang Grimm responsible for the Product Development.

Bernd Kratzer (left)

and Wolfgang Grimm (right)

In the patent Hans Lahres, head of the mathematical department and Gerd Fürter, project manager for progressives, figure as the inventors of the Gradal HS concept, HS standing for horizontal symmetry by an asymmetrical surface structure (patent US 4 606 622, application Germany 1980),see also [9] .This was a clear positioning against Rodenstock’s Progressiv R lens which was a rotated symmetrical design and should have -at least theoretically- less good characteristics for binocular vision. Carl Zeiss presented the “splines” as mathematical solution to break up the surface in tiny area elements allowing to calculate a surface without mathematical constraints. The lens manufacturing was now automated by CNC machines ensuring an excellent precision and reproducibility. Gradal HS was launched by Zeiss in 1984.

At that time Bernd Kratzer was head of the Carl Zeiss Ophthalmic Optics R&D and Wolfgang Grimm responsible for the product development.

Gradal HS: Very small symmetrical distortion by an asymmetrical design (from patent US 4 606 622)

The Gradal HS demonstrated real progress as regards the visual performance of PPLs’ which explains that at the beginning of the nineties it became a reference on the European market.

In our global analysis of this period we have still to have a look on the Asian Pacific region. Here two countries play a predominant role – Japan and Australia . In Japan Varilux was distributed by Hoya through a 50/50 joint-venture with Essilor . This joint-venture lasted until 1986 when Hoya launched its own brand Hoyalux [3]. Very innovative at that time was Seiko/Hattori which around 1985 had already launched a series of 4 progressive lenses under the umbrella brand P1. With regard to the global PPL sales these 2 companies ranked behind Rodenstock and Zeiss.

In 1960 in Australia a company with the name of SOLA was founded. It was pioneering the development of plastic lenses and at the end of the 1960’s started first overseas operations in Japan. Its turnover in 1981 was only about $ US 40 million and so it was about 6 to 8 times smaller than Essilor or Rodenstock at that time[10]. But between 1985 and 2000 it would become the most powerful competitor of Essilor for the leadership of the PPL market, particularly in the USA. A special chapter is dedicated to SOLA below.

So between 1980 and 1990 6 major companies were competing with Essilor in the progressive lens market: AO and Sola in the USA , Rodenstock , Zeiss ,Hoya, Sola in Europe and Hoya, Sola and Seiko in Asia. There were also some smaller companies such as BBGR, Univis, Younger and Polycore launching their own products . Following the multiplication of the optical companies manufacturing, promoting and selling progressive lenses the global sales increased steeply. At the end of the eighties the market volume was about 30 million lenses [11], i.e. between 1975 and 1990 the worldwide market grew by about 10 times.

More and more opticians gained experience in adapting and selling progressive lenses. The growing conviction that the varifocal lens is the most comfortable correction for the presybyope, accelerated the replacement of common corrections as single vision and bifocal/trifocal lenses. So in the USA where approximately one out of two lenses was a multifocal lens the growth potential was very high.

Until the arrival of the first competitive progressive lens AO Ultraview in 1975 [6] Essilor’s market share logically was 100 %. In the following years with an increasing number of new progressive product launches competition gained continuously market share which in 1990 in the USA was about 60 % [3].

The image of Varilux 2 was ageing and the competition attacked this fact with aggressive product positioning (see Rodenstock) and advertising (see Sola). The ECP’s tested the new designs with success and also wearer tests underlined their performance. In 1988 Essilor launched the first Multi-Design lens Essilor VMD/ Varilux Infinity, which could slow down the market share erosion [3].

At that time the USA were becoming the biggest regional market for PPL’s in the world overtaking Europe. Moreover the potential for progressive lenses was very high in the US because of the high bifocal/trifocal share of the presbyopic market. So the leadership on this market was strategically key for a solid worldwide number one position. In 1971 SOLA had formed a sales operation in Chicago and opened a manufacturing facility in Sunnyvale, California in 1975. In 1984 it launched its first progressive lens Graduate/VIP and in the following 10 years SOLA’s turnover grew by 15 % per year. SOLA represented a serious threat for the Essilor leadership of the US PPL market.

4.2 SOLA, from a local supplier to a world leading company

Comment Werner Köppen: The chapter about Sola has been partly written by my friend Kevin O’Connor. Kevin was responsible for major projects of the VIP development such as manufacturing, wearer tests, competitors’ product analysis and patent screening.

Later he joined Essilor and we worked together in the worldwide Quality and Standards’ organization.

ISO meeting 2004 in Paris: Kevin O’Connor (second from left) and Werner Köppen with wives Trish and Bärbel and members of the Chinese delegation

SOLA’s history is laid down in the book written by the Australian historian Rob Linn “Breaking the mould”. So the photographs in the Sola chapter are by courtesy of Rob Linn.

SOLA’s history started in 1956 with a research team experimenting on the production of plastic lenses in Adelaide. In 1960 this group formed a company which was incorporated as Scientific Optical Laboratories of Australia. So, different from all its future big competitors SOLA was a very “young” company. In its homeland Australia its first plant for mass production was situated in Adelaide . From the middle of the 1960’s on it started its first overseas operations in Asia with Japan and Hong Kong (later followed by Taiwan). The first ventures in Europe were in Italy, UK and Germany. In 1975 SOLA US moved to Sunnyvale and in 1978 to Petaluma, California. Mass production facilities were developed for semifinished, moulds and stock lenses in Brazil, Italy, Singapore, Sunnyvale, California (later Petaluma, California), Ireland, Mexico and finally China in 1989. In 1988 SOLA’s corporate headquarters moved from Australia to Menlo Park, USA.

In 1979 SOLA was acquired by Chance Pilkington, an English company, which was the largest glassmaker in the world. At that time SOLA’s revenues were about $ US 40 million, about $ US 100 million in 1986 and $ US 250 million in 1992. In 1995 SOLA debuted on the New York stock exchange and announced in 1996 the acquisition of American Optical Corp. and Neolens, a producer of polycarbonate lenses .The first financial figures as a publicly traded company announced by SOLA for the year 1996 were sales of $388 million and an operating profit of nearly 16%. In 1998 the sales were up to almost $ 550 million. For SOLA this period until the late nineties was an era of exponential growth. Being at the bottom of the world’s top ten ranking of the lens manufacturers in 1980 they reached the number 2 position at the end of the 1990’s.

In spite of this fact in 1993 Chance Pilkington, strongly indebted, sold SOLA for $ US 315 million to the investment firm AEA.

In 2005 the German optical group Carl Zeiss and a Swedish private equity firm EQT acquired SOLA for a value of $ US 1.1 billion.

SOLA’s development to a world leading company in the ophthalmic optical field is tightly linked to the success story of the SOLA VIP in the USA.

The beginning: In 1975 Dick Kapash joined SOLA as CEO of its US subsidiary. In the SOLA organization he was first to recognize the market potential of progressive lenses and to strongly propose developing this new lens type.

He hired the mathematicians and optical engineers Eric Barkan, David Sklar and David Spector with whom he had already worked before in the Optical Science Group in California. In the following 2 years this small team under the lead of Eric Barkan created the mathematical concepts and generalized mathematical design tools for an original progressive lens design.

This fundamental work was not immediately actioned because SOLA focussed on the development of an different design concept for the prespyopia correction, known commercially as Smartseg. This was a combination of the flat top bifocal, very popular in the USA, and the progressive surface. Within the segment power was radially increasing providing functional intermediate and reading portions at all angles of gaze.

Eric Barkan (right) and Michy Kris

The development: Smartseg was not the great commercial success SOLA had hoped for and so from 1982 on SOLA shifted its marketing attention to the “no-line bifocal lens“ strongly supported by John Heine , CEO of SOLA since 1982. A joint Australia/USA development team was formed under the direction of Ted Ellis from Chance Pilkington. The R&D team in USA had leadership and guidance from Tom Balch.

Patents from Eric Barkan and David Sklar (US 4 676 610 filed 1983 and US 4 838 675 filed 1987) describe the mathematical method to obtain the progressive surface with the help of a merit function. The performance characteristic for the merit function is at least one of the parameters astigmatism, mean power, orthoscopy and others (see also [12]).

Kevin O’Connor (right) and Michy Kris

Kevin O’ Connor, Australia, was in charge of the development of the manufacturing process which occurred mostly in Adelaide. Michy Kris, a mathematician working with Kevin translated the theoretical design results into the necessary machining parameters. The final lens design was chosen by an iterative process based on the designing method conceived by Eric Barkan taking into account data of extensive wearer trials, competitor product analysis as well as the competitor patent field.

The manufacturing process chosen was thermal slumping using refractory formers milled by CNC milling machines. The development of vacuum slumping allowed the creation of more consistent and predictable glass mould casting surfaces.

New metrology devices were developed including for example Ronchi/Moire technologies to guarantee the very good reproducibility of the VIP lens which was one of the characteristics used by Sola Marketing to demonstrate the superiority of their lens in comparative advertising.

Production started in Australia in 1983 and the new progressive lens was launched as Graduate in Australia and Europe in 1984 and as VIP in the USA in 1985.

The VIP was one of the most successful progressive lenses in history and after a period of 25 years was withdrawn from the market in 2009.

In 1990 the PPL sales from SOLA , AO, Younger Optics, Univis ,Vision Ease/Orcolite, Signet Armorlite and others represented about 60% of the US market, where Sola had the biggest share [3].

Dick Kapash (middle) and Sir Antony Pilkington (right)

There are 3 primary reasons for SOLA’s outstanding success

# The very good performance of the VIP lens (and later XL)

# VIP was regarded as a reliable lens which could be trusted by ECP’s

# Innovative Marketing Techniques developed by SOLA USA

For the wearer the VIP design was distinguished by large viewing zones for near, far and intermediate vision and a generally good adaptation. Together with the high manufacturing consistency from lens to lens VIP was very reliable creating a high level of confidence for the prescriber.

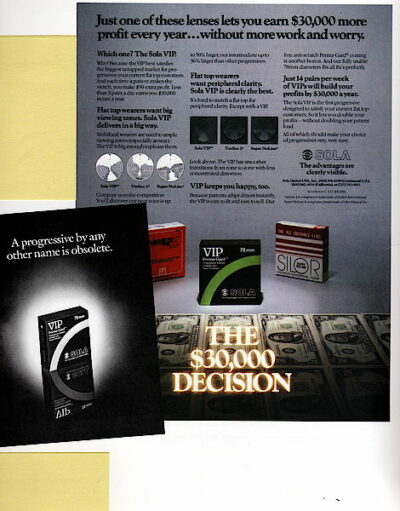

After its launch in 1985 the market share of VIP was increasing strongly. In 1987 SOLA introduced the XL progressive lens – softer than the Graduate/VIP lens, and it too enjoyed commercial success. The introduction of the mid index material Spectralite reinforced SOLA’s position as challenger. In 1991 and 1994 VIP Gold and XL Gold were introduced in the thinner and lighter Spectralite material.

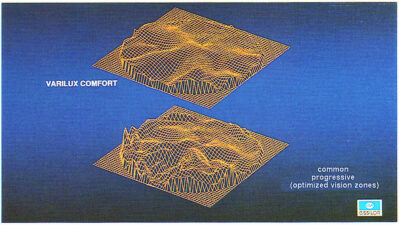

The success of SOLA during this period is also due to the innovative marketing campaign set up by Bernie Freiwald and supported by Mark Mattison- Shupnick. In the USA where comparative advertising is permitted Freiwald’s marketing concept was going ‘head to head’ with competitors. In these advertisements Sola systematically used contour plots showing that the optical characteristics of VIP and XL lenses and their consistency were superior to Varilux 2 and Super No Line (distributed by Silor Inc., Essilor’s second US subsidiary). Contour plots are relatively easy to measure and to interpret, because they describe primarily the physical properties of the lens. So this way was a clever strategy to attack the Essilor lenses, which were developed according to physiological criteria, not so easy to demonstrate by a technical measurement device.

Sola advertising comparing VIP with Varilux and Super NoLine using contour plots

So in the middle of the nineties Sola by its innovative product range, well adapted to the US market, its growth of sales per year of nearly 15 % and its excellent profitability was a real threat to the leader Essilor on the US market.

In the middle of the eighties Essilor decided to develop a new Varilux generation. It was also a new generation of R&D and Marketing people who prepared the ground for a renewal of the Varilux brand.

Prix “high-tech” of the French Magazine “Figaro” for the Multi- Design concept Gerard Obrecht (left), Maurice Dufour (third from left) , Werner Köppen(right)

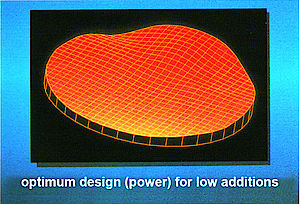

The key research people for this project were Jean Louis Mercier (Director of Research) , Christian Miège, Gérard Obrecht, Claude Pedrono and Dominique Meslin. On the Marketing side the responsible Product Manager was Werner Köppen who had left Rodenstock for Essilor. Starting from the observation that for the low adds the specialty progressive Alpha for emmetropic presbyopes was more appreciated by the wearer than Varilux 2, the idea of the Multi- Design progressive was born. Each add, so each age class of presbyopes should have its own characteristic and optimum design according to the evolving needs and constraints of the presbyope with age. Up to this time the designs for the different addition powers were homothetic, i.e. their contour plots, if divided by the corresponding addition power, were identical. Essilor launched its first Multi- Design progressive Essilor VMD in 1988.

In the USA the brand name of the new lens was Varilux Infinity and in spring 1988 the Multi- Design concept was presented in two big meetings organized by Varilux Corp. in San Francisco and San Antonio [13].

Varilux Multi- Design: Different designs for different add powers

One of the challenges for the new R&D team was to create physiological analysis techniques/ tests as well as powerful and flexible calculation tools which allowed to improve systematically and continuously the performance of the progressive lens.

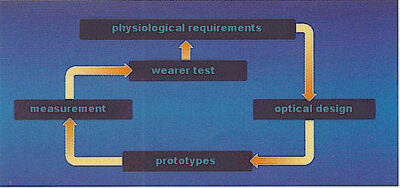

The Design Loop (boucle dioptrique)

In 1989 Jean-Pierre Chauveau joined the Essilor Research team and was in charge of the Dioptric Group which conceived a new method, the Design Loop („boucle dioptrique“). Starting from a first model of physiological requirements the research people calculated the design, which after the realization of the first prototypes was assessed by the wearer in extensive wearer tests, their feedback taken into account in somewhat modified specifications and a second improved design, tested again and so on. So this iterative process was a guarantee that the design was an optimum solution for the visual needs of the wearer. Varilux Comfort was the first Essilor progressive lens which was developed following the „boucle dioptrique“ process [14] .

From left: Jean-Louis Mercier, Patrick Bertrand and Werner Köppen (1993)

The launch of Essilor VMD/ Varilux Infinity slowed down Essilor’s loss of market share but, especially in the USA, the pressure by Sola remained very strong.

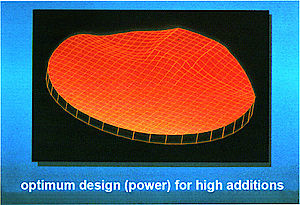

To develop a special design for each age class of the presbyopic wearer means a complete database of physiological characteristics. Until ‘91 the young research team under the responsibility of Jean-Louis Mercier had made a big progress in their knowledge about the visual behavior of persons with different age with and without spectacle lens correction. They developed new mathematical and optical tools in order to engineer a design process capable of high performance and reactivity. This team designed daily several new progressive equations corresponding to different physiological concepts in order to select possible candidates for exhaustive comparative wearer tests. A new optical measurement method ( patent US 5 581 347 , filed in France 1993) and sophisticated CNC machines allowed to manufacture the prototypes for the wearer tests respecting a tight timetable and in exact compliance with theoretical data over the whole surface. As a major result of this new process it was for the first time possible to conceive progressive surfaces which were fully aspherized -which is beneficial for the peripheral and dynamic vision- nevertheless maintaining a high quality for foveal vision.

These results offered the opportunity to develop a new progresive lens with exceptional performance following the new iterative Design Loop process. In the middle of 1991 Werner Köppen, now Marketing Director for Essilor Progressive Lenses set up together with the research team the specifications for a second generation of the Multi-Design concept.

Jean-Pierre Chauveau, Dioptric Group

Christian Miège, Physiological Optics

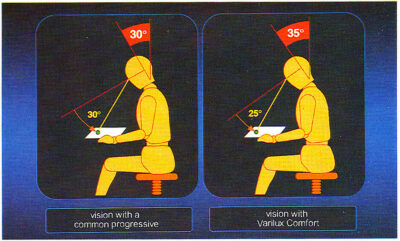

The physiological research work concentrated on the comfort of head posture and head and eye movements ( patents US 5 270 745 and US 5 272 495, filed in France 1991) and is described in a paper by Christian Miège and Claude Pedrono [15]. Wearer tests confirmed that Varilux Comfort was distinguished by a more natural vision than with previous progressive lenses with head and eye movements close to the viewing conditions without spectacles. Compared to natural vision the wearer when reading with progressive lenses has to lower the gaze more and to lift the head a little. By a rather short power increase the Varilux Comfort design reduced these changes of the visual behavior considerably. For the progressive lenses before Varilux Comfort a short progression meant however inevitably a rather high peripheral astigmatism. But the Varilux Comfort design is soft and smooth and thereby offers excellent peripheral and dynamic viewing conditions ( patent US 5 488 442, filed in France 1992).Varilux Comfort was the first progressive lens which combined the advantages of a „hard“ and a „soft“ design, large fields for foveal and peripheral vision and good dynamic viewing conditions [16].

3 patents for Varilux Comfort : a physiological meridian and a soft surface structure with wide foveal vision fields

Varilux Comfort: the benefits of a hard and a soft design, a high and large NV zone and a soft periphery

This vital project for Essilor was managed with high professionalism by Denis Blandin, also Product Manager for Varilux Comfort. Jean-Marc Leroy, Technical Product Manager, was in charge of the technical definition of the product, as regards geometry, power range, materials …., which is so important for the Rx production and a complete, competitive product range.

From left: Jean-Louis Mercier, Tim Thurn, Nathalie Bar, Jean-Pierre Chauveau, Rod Tahran, Christian Miège

After a promising market test in France, Netherlands and Germany Varilux Comfort was launched 1993 in Europe and 1994 in the USA and Asia.

In the competition for the progressive lenses leadership the power and organization of the distribution network was crucial.

Introducing the first progressive lens Essilor learned early that to have the new lens accepted by the market a strong local support was an indispensable prerequisite. So when launching Varilux in the 1960’s and Varilux 2 in the 1970’s, Essilor created a dense worldwide network of distributors or subsidiaries: in UK, Spain, Italy, Germany, Switzerland, Belgium, Finland, Portugal, Netherlands in Europe, Dr. Carlos Bessa in Brazil, a joint venture with Hoya in Japan and in 1975 the US subsidiary Multi Optics Corporation (later Varilux Corp. for the Varilux distribution). In the 1980’s many of the distributors became Essilor subsidiaries and new subsidiaries in the Asia Pacific zone were founded.

For its competitors the situation was different. The geographical coverage of their sales organizations was often limited or in the hands of distributors only.

In Europe in the beginning of the 1990’s Zeiss and Rodenstock were ranked number 2 and 3 behind Essilor, but Sola was catching up also here. Zeiss was particularly successful due to the excellent quality of the Gradal HS design. In the first half of 1993 Essilor rolled out the new Varilux Comfort in about 15 European subsidiaries. The superior performance of the lens tested against the best designs on the market, and the powerful market introduction across all Europe made this launch an outstanding success. It was also a big personal achievement for Jean-Luc Bayssac, Director of the European subsidiaries.

Jean-Luc Bayssac (up,left) (European subsidiaries meeting ’94)

In the USA SOLA had its head office in Petaluma, California, the two Essilor distribution circuits Varilux and Silor had moved to St. Petersburg, Florida. Initially Varilux Corp was in San Francisco and Silor Inc. close to New York.

Michael Ness, VP Marketing for the Varilux Comfort launch (middle), (1997)

At that time it was a specific characteristic of the US market, that the manufacturers did not sell directly to the ECP but passed by the labs. Varilux Corp was distributing the Varilux brand to somewhat more than 100 selected, certified Varilux labs, and Silor was making business with the rest of the US labs and the chains.

After Varilux Comfort had been introduced successfully in Europa it was launched in the USA in 1994.

Also at Varilux Corp. a new generation of marketing and sales people were now leading the activities. The key people organizing this launch were Michael Ness, VP Marketing and Bob Colucci, VP Sales supported by Dominique Meslin from the Technical Marketing side. The product presentations by Dominique Meslin were also a big help for the market introductions of Comfort in Asia and South America. With the successful launch of Varilux Comfort SOLA lost its competitive edge concerning the product and Varilux Corp. regained lost market share.

Bob Colucci, VP sales for the Vx Comfort launch (with Bärbel Köppen)

In 1996 Essilor made a major strategic move when it decided to enter the US lab business in purchasing the lab network Southern Optical in Greensboro, North Carolina and the Omega Group in Dallas. This decision was taken under the responsibility of the Essilor chairman Gerard Cottet and not without risk because Essilor was now in competition with its customers. This was the beginning of Essilor Laboratories of America which under the management of Hubert Sagnières developed to the biggest lab organization in the USA and gave Essilor the advantage to control distribution and quality of its own products. In contrast Sola’s senior management decided not to invest in proprietary labs.

Gerard Cottet (left), Essilor chairman from 1991 until 1996, (1997)

This was certainly another major factor explaining why the growth of SOLA in the following years slowed down.

Finally there were important senior management changes in the USA: In the beginning of the nineties several key people as Dick Kapash and Tom Balch left SOLA US.

The Varilux Comfort proved to be the “problem free progressive “. Its launch had a deep impact on the market balance. From 1993 on the sales of Varilux showed a sharp increase and between 1993 and 1999 grew by 80 % from 120 million to 214 million [17]. Today Varilux Comfort is the most sold progressive ever. It was one of the cornerstones for the strong and steady growth of Essilor’s revenues in the second half of the 1990’s and the beginning of the new century under the responsibility of the new chairman Xavier Fontanet.

In 2010 the worldwide progressive lens market has a volume of nearly 150 million lenses [11]. Today Essilor is the market leader for progressives with 1 out of two progressive lenses sold worldwide. As history showed, this success is due not only to the advantage of being the inventor with the capacity to renew the brand image, but also to the commercial policy of integrated manufacturing and proprietary subsidiaries.

Around 1980 American Optical was the number one manufacturer in the global ophthalmic optics industry. Second and third were Rodenstock and Essilor. Rodenstock’s sales had tripled in the seventies [18] and had now reached about $ US 250 million. The revenues of Zeiss and Hoya were distinctly smaller and the net sales for SOLA were only about $US 40 million.

In the following years this ranking changed fundamentally. Between 1980 and 1990’s Essilor approximately quadrupled its turnover and and became the world leader in the ophthalmic optics industry. Different from most of its competitors Essilor had a global business approach and established mass manufacturing sites in Europe, Americas and Asia and a worldwide network of own subsidiaries or distributors with Rx labs. The results of this production and distribution power were low manufacturing costs, high reactivity, good service and quality control of its products.

AOC was present in many segments of ophthalmic optics as spectacle lenses, frames, contact lenses, safety goggles, focimeters and was traditionally innovative in lens design [19]. AO‘s business was largely focused on the US market and so was certainly more affected by the FDA impact regulations for spectacle lenses than some of its major competitors. In the 1980’s and 1990’s glass lens manufacturing (bifocals!) in Southbridge was closed, the contact and fiber optics business sold and the whole plastic manufacturing moved to Tijuana. In 1996 AOC was purchased by Sola.

The German companies developed their business mainly on the very profitable German market. So in 1980 the German market represented about 60 % in Rodenstock’s turnover [18].

SOLA had a similar global strategy as Essilor and, as described above, their turnover and market share grew almost exponentially. At the end of the 1990’s SOLA reached the number 2 position in the worldwide ranking of the spectacles manufacturers.

It is remarkable that it was during the period of the 1980’s when competition attacked Essilor’s leadership for the progressive lens, particularly in the USA, Essilor climbed up to the number one position of the ophthalmic optics business. When Essilor became number 1 it realized 2/3 of its turnover in overseas business [3].

The following years saw an exponential increase of new progressive lens types. On the one hand more and more middle sized manufacturers developed their own designs, on the other hand the market leaders completed their product ranges and “updated” their leading brands. So for example Sola launched between 1997 and 2003 Percepta,Continuum, SOLAMAX and SOLAOne and Essilor developed the following Varilux generations Varilux Panamic (launch 2000) and Varilux Physio (launch 2006). Today almost all the “all-purpose” progressive lenses are of the Multi Design type varying the surface structure depending on the addition and ametropia. These new designs are based on the latest results in physiological optics research, as well as in IT and automation technology. Varilux Physio for example is characterized by correcting not only low order aberrations as astigmatism and power error but also higher order aberrations as Coma improving so visual acuity and contrast sensitivity.

In 1997 Seiko introduced the first progressive lens using free form technology. The progress in CNC grinding and polishing machines allowed the direct manufacturing of the finished progressive lens, different from the common way to grind the prescription in the back surface of a progressive semi-finished blank. After a first stage of personalization with a Multi-Design lens now for each wearer the individual lens could be conceived and produced. In 2000 the German companies Rodenstock and Zeiss launched respectively Impression ILT and Gradal Individual which provided the optimum design for the particular wearer taking into account his individual correction and the specific frame and lens centering data. For Ipseo developed by Essilor the design could be adapted to the head-and eye movement pattern of the wearer.

In the mid term this new manufacturing process is a challenge for the structure of the industry as well for the big manufacturers with regard to the traditional production technology as for certain distributors because it offers (at least in principle) the possibility to manufacture and sell their own brand.

In the long term it will be interesting if technical developments such as diffractive power lenses, gradient index lenses or even full field variable focus lenses can improve the quality and comfort of presbyopic correction with spectacle lenses. There are already research articles published and patents filed on these topics. Today these new technologies are still very complex and expensive and there is another obstacle:

Already today the correction with progressive lenses has a high level of comfort, which will not be easy to improve.

The progressive lens is as a sophisticated product also a very sensitive product. Only when it is precisely positioned in front of the eyes the wearer can fully experience the design performance. So only the rigorous work and skill of the optician makes it a success. In this sense the progressive lens is the ideal product for the tight cooperation between manufacturer and ECP in the ophthalmic optical industry.

In the beginning the ECP’s had to learn all the special aspects of the new lens type, how to determine the correct centering position of the lens relatively to the eye, how to measure precisely the interpupillary distance for far or near vision using special devices, how to center the lens using the painted markings, verify the correct marking with help of the engravings, control the power of far vision and add of the progressive surface. The new lens required a lot of new expertise from the optician. So quite naturally the increasing experience of the ECP’s was a cornerstone of the market penetration of the new product, which was so different from the accustomed single vision and bifocal lenses.

During the first years of the Varilux launch the number of returns was very high mainly because of the centering errors . So Essilor created Varilux consultants in the different markets supported by corresponding experts at the head office to educate ophthalmologists and opticians how to handle the new lens and to offer trouble shooting. Michel Gillet, a pioneer of the Varilux market introduction, was initiating and organizing these activities. Additionally at the beginning in some markets the launch was restricted to a limited number of opticians or labs particularly committed to the innovation . That thorough and permanent training is key for the PPL success has been demonstrated by the problems when American Optical launched its Ultraview in the US in the middle of the 1970’s. The number of non adapts was rather high and the launch accompanied by an expensive promotion campaign did not meet the expectations of AO [3]. SOLA supported the introduction of their progressives by a “hotline” organization which had the mission to train the ECP’s and the labs on the new lens type and to take care of trouble shooting.

As the inventor of the progressive lens Essilor was also the pioneer in the service field for PPL’s. In special courses and seminars the new characteristics and methods were presented and explained, instruments and working tools facilitating the determination of the pupil distance, the identification of the engravings and the marking of the reference points on the lens surface were developed. So the progressive lens with its strong interdependence between product performance and ECP skill contributed strongly to the partnership between manufacturer/labs and ophthalmologists/optometrists/opticians.

With the introduction of the personalized free-form lenses these devices became more elaborate offering semi-automatic measurements of the parameters of the frame, its position in front of the eye of the wearer, the visual habits of the wearer and so on. In the future manufacturers will have to focus their efforts still more on the sophistication of the service. One direction of these efforts should be to involve more the consumer. The process of the lens purchase should become an event, and should be embedded in a series of attractive services. In such an “experience environment” customer information, optometric analysis, product demonstration (simulation) and customer specific product selection has to form a single unit, making the purchase of lenses a memorable experience to the customer [20].

Publication in German : Optometrie 2/2011 and Optometrie 3/2011

Between the years 1975 and 2000 the character of the Opthalmic Optics market experienced a major change from basic medical care to a business with High Tech products and personalized customer service. Triggered by the breakthrough of the progressive lens the technological progress during these years developed a small range of standard products to a complex portfolio of surface designs and added values. The concentration of distribution in chains and purchasing groups with a common label increased dramatically the power of these distribution channels and obliged the independant ECP’s to differentiate their business by new Marketing approaches and specific optometric expertise. During these years the ranking of the big manufacturers changend fundamentally.

- Colin M. Sullivan and Colin W. Fowler: Progressive addition and variable focus lenses: A review. Ophthal. Physiol. Opt. , Vol.8, 1988

- Bernard Maitenaz: De Franklin à Varilux…. . Points de Vue, no.60, spring 2009

- Jean-Charles Le Roux: L’épopée Varilux, éditions Perrin, 2007

- Bernard Maitenaz: Four Steps that led to Varilux. Am. J. Optom., Vol. 43, 1966

- David Volk and Joseph W. Weinberg: The Omnifocal Lens for Presbyopia. Arch. Ophthalmol., Vol.68, 1962

- Whitney’s AO Lens Designers Page, www.dickwhitney.net

- Günther Guilino and Rudolf Barth: Neue progressive Flächen. Deutsche Optikerzeitung, no. 11,1980

- Günther Guilino and Werner Köppen: Progressiv R: The new progressive lens from Rodenstock.

The Ophthalmic Optician, March 1982 (available on this site) - Bernd J.L. Kratzer and Gerd Fürter: Gradal HS, eine neue Konzeption bei Gleitsichtgläsern.

WVAO Sonderdruck, Vol.35, 1983 - Rob Linn: Breaking the Mould: the history of Sola Optical. Adelaide S.A., 2000

- Hélène Amidieu: Influence des verres progressifs sur le marché de la correction de la presbytie. Points de vue, no.60, spring 2009

- Darryl Meister: Optics of Progressive Lenses. www.opticampus.com

- Werner Köppen: Varilux Multi-Design, increased comfort for the wearer, more reliability for the ECP. Deutsche Optikerzeitung, no.9, 1988 (available on this site)

- Jean-Louis Mercier, Christian Miège, Gilles Le Saux, Jean-Pierre Chauveau : The design loop for progressive lenses. Points de vue, no. 34, spring 1996 (available on this site )

- Christian Miège and Claude Pedrono: Varilux Comfort: The physiological concepts on which this new design is based. Optometriste, vol.15, no.5, 1993 and Optical Prism, oct.1993

- Werner Köppen: Varilux Comfort. Deutsche Optikerzeitung, no.9, 1993 (available on this site)

- Claire Feuilly: 300 Million Varilux sold since 1959. Points de vue, no. 49, autumn 2003

- Rodenstock: 100 Jahre für besseres Sehen, September 1977

- Dick Whitney: AO History Chronology, www.dickwhitney.net

- Werner Köppen: A view of the development of the global ophthalmic lens market. Deutsche Optikerzeitung, no.7, 2009 (available on this site)